Museum

Germanisches Nationalmuseum

The Germanisches Nationalmuseum is the largest museum dedicated to the cultural history of the German-speaking world. Founded in 1852, its collections number around 1.4 million objects.

Approach & Solution

In order to digitize its archives, it chose to equip itself with the SupraScan 2A0, and is very satisfied.

The museum was founded in 1852, and today its collections number around 1.4 million objects, including the library. The museum’s archives span hundreds of metres of shelving. Our collections range from prehistory and early history to the present day, and include everything that can give us information about our culture.

“Speed is the first point, as well as the size of the scanning field. We can place several prints on the scanner at the same time. Once the scanning process is complete, which takes less than a minute, we can save individual prints very quickly. A second advantage is consistent quality, which we document by scanning the Munsell gray scale. Unlike the set-up time in a photo studio, the scanner is ready in the morning after just a few minutes, so we can get to work straight away. Finally, after setting up an appropriate workflow, we standardized the work on the device so that even a colleague who doesn’t know anything about photography can do it.”

Interview with Dr. Frank P. Bar, Head of Photography at the Germanisches Nationalmuseum

Discover other achievements

General Archives of the Kingdom of Belgium

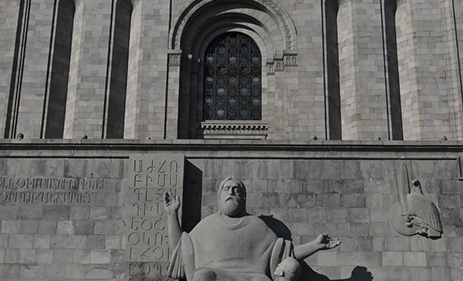

The Matenadaran

Mesrop Mashtots Institute of Ancient Manuscripts

One of the main functions of the Matenadaran’s Digitization Department is to digitize medieval manuscripts, archival documents, Armenian literature and press collections held in the Matenadaran bookshop.